Despite Challenges, Research Shows Opportunity To Increase Use of Manure as Fertilizer

Highlights:

-

The value of manure as a fertilizer depends on where it is located, how expensive it is to transport and apply, and its crop nutrient composition.

-

Livestock producers can increase the value of manure by altering their manure storage and handling methods, adjusting animal feed, adding compounds to manure, or by composting or pelletizing manure.

-

Farmers can use anaerobic digesters or thermochemical conversion processes to generate renewable energy from manure and produce valuable products such as animal bedding or biodegradable plant pots.

Animal waste, otherwise known as manure, is a valuable source of crop nutrients that can improve physical and biological properties of soil. Manure contains primary macronutrients—namely nitrogen, phosphorus, and potassium—meaning it can substitute for or complement commercial fertilizers. Manure also supplies secondary macronutrients such as calcium, magnesium, and sulfur, as well as micronutrients. In addition, manure provides organic matter and carbon, which makes it useful for improving soil health.

Despite these attributes, there are economic and environmental challenges to expanding the use of manure as a fertilizer. With a low nutrient value-to-mass ratio, manure is more costly to transport, store, and apply than chemical fertilizers. In addition, livestock production tends to be geographically concentrated in the United States, and, in certain regions, animal production generates more manure-supplied nutrients than are needed by nearby cropland. That means farmers often must transport manure longer distances to match its nutrient value with crop needs. Specifically, the nitrogen and phosphorus levels in manure often do not match the nutrient needs of crops, so farmers still must use chemical fertilizers to supplement nutrients from manure. Also, applying enough manure to meet a crop’s needs for one nutrient has the potential to create an environmental hazard from the unused nutrients left on the soil. Excess manure nutrients can leave the fields via run-off and degrade water quality, or they can enter the air.

Manure collection and treatment technologies continue to evolve and offer new economic opportunities for some farmers. These technologies can sometimes make it less expensive to transport and apply manure, adjust the nutrient ratio, or support manure’s use in producing energy and other marketable products. In addition to increasing farm revenue, improved manure management has the potential to reduce nutrient pollution in waterways and to lower greenhouse gas emissions and fossil fuel use.

A recent study by USDA, Economic Research Service identified opportunities for increasing the use of manure as a fertilizer. In 2020, farmers applied manure to less than 8 percent of the 237.7 million acres planted to seven major U.S. field crops. About 79 percent of the cropland receiving manure was planted in corn. Although corn received more manure than any other crop, manure was only applied to 16.3 percent of the land planted in corn. In addition to these field crops, hay acreage and grassland also receive manure. ERS research found that in 2006 (the most recent data available), 26 percent of all acreage with manure applied was in hay or grass.

| Estimated 2020 acres (thousands) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Commodity | Planted | Manure applied as fertilizer | Manure-applied acreage as share of planted acreage (percent) | Manure-applied acreage as share of total acres using manure (percent) | ||||

| Corn | 90,819 | 14,822 | 16.3 | 78.8 | ||||

| Soybeans | 83,084 | 1,884 | 2.3 | 10.0 | ||||

| Wheat | 44,349 | 908 | 2.0 | 4.8 | ||||

| Cotton | 12,093 | 505 | 4.2 | 2.7 | ||||

| Barley | 2,726 | 137 | 5.0 | 0.7 | ||||

| Oats | 2,984 | 358 | 12.0 | 1.9 | ||||

| Peanuts | 1,664 | 203 | 12.2 | 1.1 | ||||

| Total | 237,719 | 18,818 | 7.9 | 100 | ||||

| Note: 2020 planted acreage estimates are from USDA, National Agricultural Statistics Service’s Acreage report. 2020 acreages with manure applied as fertilizer are estimated by multiplying 2020 planted acres by the share of crop acres using manure from the USDA’s Agricultural Resource Management Survey, Phase II, 2013–19. Sources: USDA, Economic Research Service (ERS) using data from USDA, National Agricultural Statistics Service’s (NASS) Acreage report and ERS and NASS, Agricultural Resource Management Survey Phase II, 2013–19. |

||||||||

Manure Use Reflects Links Between Regional Mix of Crop and Livestock Production

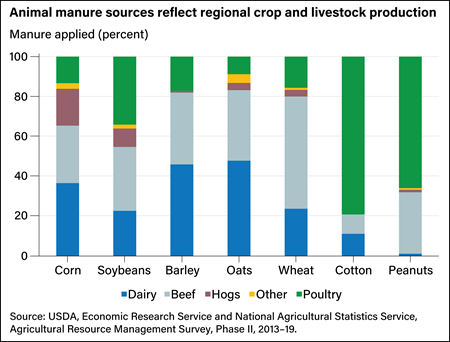

The extent to which crop farms apply manure depends on location, farm size, commodity mix, production practices, and other characteristics. Manure is expensive to transport, and local animal production largely determines the type of manure applied to regional crops. For example, because most hogs are produced in the Midwest, hog manure is applied predominately to corn and soybeans. Most chickens are raised in the Southeastern United States, so most animal waste applied to crops grown primarily in the South, such as cotton and peanuts, originates from poultry farms.

Beef cattle operations are the source of most manure applied to wheat acreage. Beef cattle are produced mainly in the Great Plains, where most wheat acres are planted. Dairies, located in the Western, Midwestern, and Northeastern United States, supply the largest share of manure applied to corn, barley, and oats.

Nutrient Balance, Price to Transport, and Application Cost Present Challenges to Increasing Value

Several factors increase the costs of using manure as a commercial fertilizer replacement. First, manure has a low nutrient value-to-mass ratio. This is partly because of its water content, which can be up to 90 percent of the total weight. The low quantity of nutrients per ton makes manure application and transportation time-intensive and costly.

High transportation costs are a particular problem when the local supply of manure exceeds local demand. In recent decades, producers have become increasingly specialized in either crop or livestock production, and livestock production has largely moved from pasture-based to concentrated feeding operations. In some regions, concentrated animal production—where animals are kept in barns or enclosed lots—has resulted in the local supply of manure nutrients exceeding the nutrient needs of local crops. The cost to transport manure creates an incentive to over-apply manure nutrients on nearby land. The application of excess nutrients to the land can have negative implications for water quality and aquatic ecosystems. A local surplus of manure also reduces incentives for farmers to apply and store it in ways that conserve manure’s nutrients. Nitrogen is susceptible to evaporation and becomes volatile when manure is stored in lagoons or when it is applied to the soil surface. That can lead to odor, health, and environmental concerns.

In addition, manure has a nitrogen-to-phosphorus ratio that does not align with most crops’ nutrient requirements. Applying enough manure to meet a crop’s nitrogen needs may lead to an overapplication of phosphorus, resulting in nutrient runoff and leaching and pollution of surface and groundwater. To avoid nutrient pollution from excessive manure application on land, farmers may need to restrict manure applications and apply supplemental nitrogen from commercial fertilizer to meet a crop’s nutrient requirements.

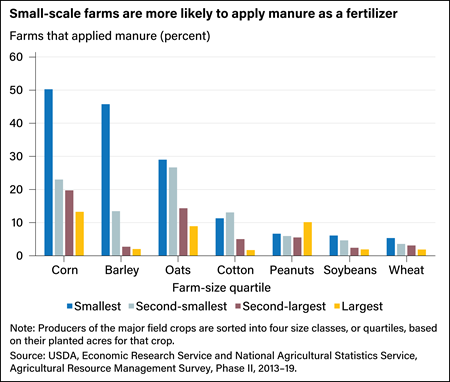

The additional labor and time required to apply manure helps to explain why small-scale farmers are generally more likely than large-scale farmers to apply manure to their crops. To study this, ERS researchers sorted the producers of the major field crops into four equal size classes, or quartiles, based on their planted acres for each crop. Half of the corn farmers in the quartile with the fewest acres applied manure, compared with only 13 percent in the quartile with the largest number of acres. Operators of large farms may face labor constraints, and thus prefer commercial fertilizers, which can be applied more precisely and quickly than manure. This pattern may also be partly explained by specialization. Larger crop farms are less likely to integrate animals into their operation, so they are less likely to have manure available for application.

Manure storage systems affect the manure’s composition (such as its moisture content), fertilizer value, and potential nonfertilizer uses (such as for energy production or industrial products). They also dictate the equipment a farm needs to manage the manure. Farms with beef cattle and poultry are most likely to use dry storage. Farms with pigs and dairy cows typically store manure as either liquids in lagoons, slurries in pits, or dry manure.

Some storage systems reduce manure’s water content. Keeping water out of manure—or storing the manure in a dry form—makes it less expensive to transport. Removing liquid also preserves the manure’s nitrogen content and increases its fertilizer value. However, if nearby crops don’t need much nitrogen and phosphorus, preserving nitrogen won’t necessarily increase manure’s value to the farmer. Instead, the higher nitrogen content may require the farmer to transport the manure farther to find land on which to apply it at rates that do not violate Federal or State environmental regulations.

Farms can introduce water-reduction technologies at the manure collection stage or storage stage. Wet-dry feeders in swine production have been shown to reduce water in pig slurry manure and make the slurry a more concentrated source of fertilizer nutrients. Lagoon or pit covers help to conserve nitrogen and prevent rainwater from diluting the manure, as well as reduce odor issues. Solid-liquid separation technologies work by separating manure’s nutrient-dense content from the water so both parts can be managed for maximum benefit.

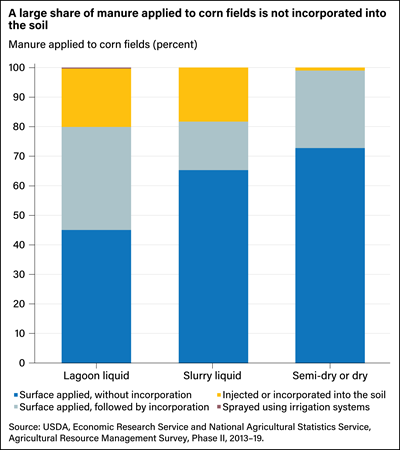

The value of manure as a fertilizer also depends on the manure application method used. Injecting manure below the soil surface or incorporating manure shortly after surface application conserves more nutrients and increases the fertilizer value. Surface application without incorporating or applying manure through an irrigation system results in less nutrient retention and lower fertilizer value.

How to decide which application method to use depends in part on the liquid content of the manure, which in turn depends on the animal that produced the manure and the storage system. Poultry and beef feedlot manures are typically dry or semisolid. Almost all dry or semisolid manures are applied through surface applications. On corn fields, less than 30 percent of surface-applied manure is incorporated into the soil.

Lagoon and slurry liquid manure typically comes from swine or dairy farms, where it is common to use water to wash manure out of barns, creating waste with high water content. A greater percent of surface-applied lagoon liquid applications involve incorporation into the soil compared with slurry liquid. For corn, about 20 percent of lagoon and slurry liquid manure is injected or incorporated at application. A small percentage of liquid manure stored in lagoons is sprayed through irrigation systems.

More Than Three-Quarters of Manure Is Applied on the Farm Where it Is Produced

According to data from USDA’s Agricultural Resource Management Survey (ARMS), 78 percent of applied manure comes from crop and livestock integrated farms. Only 14 percent of applied manure is purchased from other farmers, and 8 percent is obtained for free. There is potential for expanding manure application to cropland. The market for manure as a nutrient source for organic crop production is one source of such expansion. Under National Organic Program standards, manure from conventional animal operations can be used in organic food production. Farms or other agribusinesses may be able to develop other opportunities to market manure as a fertilizer if they can incorporate new ways to process it to compete with chemical fertilizers. Possibilities include:

- Adjustments to improve nutrient content. Over the past several decades, it has become increasingly common to supplement feed with distillers dried grains (with solubles), phytase, or synthetic amino acids. These ingredients can change the nutrient content and value of manure. Another option is to add compounds such as nitrogen, alum, acid, biochar, and clay to better match manure nutrients with crop needs and save time and cost in fertilizer application.

- Composting. Between 2015 and 2018, only about 4 percent of manure-fertilized farmland received composted manure. In composting, bacteria stabilize manure’s organic matter and nutrients. Composting also reduces the overall volume of manure, bedding, and other organic matter being composted, and it reduces the number of pathogens. Composting improves manure’s value as a soil additive and fertilizer and helps to reduce the potential for air and water pollution.

- Liquid-solids separation. Technologies exist that remove coarse solids from water-intensive dairy manure systems, separate fine solids for nutrient recovery, and reduce the moisture content in solids to make them more suitable for other processes. Coarse solids can be used to improve soil. The fine solids contain most of the manure nutrients, and these can be developed into valuable fertilizers. Removing water or drying are generally required to prepare manure for value-added processing, including the manufacture of fiber products and energy generation.

- Pelletizing. Raw or composted manure can be processed into pellets with a more consistent and denser product. This process conserves manure nutrients, allows for better control of nutrient application, and reduces storage and handling costs. Because pellets are less costly to transport than raw manure, they can make it more economical to redistribute manure nutrients from areas with excess manure nutrients to areas with too few nutrients. Certified organic production is a potential growth market for pelletized manure.

Manure Has Role to Play in Generating Renewable Fuels and Other Coproducts

Some developing technologies obtain value from manure for purposes other than fertilizing crops. In particular, anaerobic digesters linked with livestock production can be used to generate renewable natural gas from manure. An anaerobic digester is an airtight vessel in which bacteria digest, or decompose, organic waste such as manure. Digester coproducts also can be processed into animal bedding or plant substrates. In anaerobic digestion, bacteria generate a biogas containing methane that can be captured and used as a source of energy, thereby reducing greenhouse gas emissions. The anaerobic process turns manure and other organic wastes into a more consistent product, called digestate, and reduces the potential contamination of waterways. On-farm anaerobic digester benefits include odor reduction, air quality improvement, and the supply of digestate as an alternative to chemical fertilizers.

A simple application of the biogas produced by digesters, which requires little to no additional processing, is to burn it onsite to generate heat or electricity for local use or sale. Purifying the biogas creates a product that is comparable to natural gas and can be injected into pipelines and used in large-scale electric power plants or as fuel for vehicles.

The relatively high capital cost of anerobic digesters has limited the use of this technology to larger operations (such as dairies with at least 500 cows). In addition to construction costs, anaerobic digesters require constant maintenance and supervision to maintain the temperatures, consistency, and acidity needed for decomposition. Trained operators must supervise the process to prevent leakage, explosion, asphyxiation, or hydrogen sulfide poisoning. To address the barriers to digester technology, USDA provides cost sharing to farming operations interested in adopting these technologies, including the initial on-farm feasibility study.

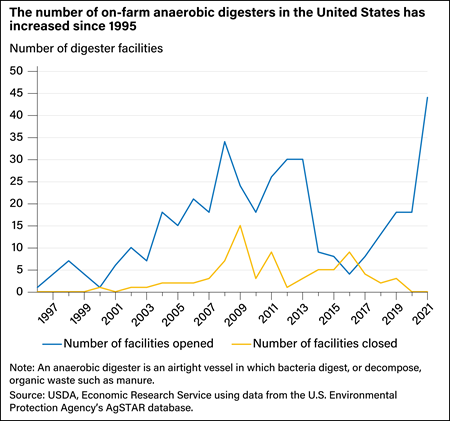

The number of on-farm anaerobic digester systems steadily increased during the past several decades, according to tracking provided by AgSTAR, a collaborative program sponsored by the Environmental Protection Agency and USDA. A total of 355 systems were in operation or under construction in 2021. Recent growth in the number of digesters corresponds to the increase in demand for renewable fuel resulting from carbon credit trading and incentive programs. More covered lagoons have been built as their costs have come down. Many of the newer digester projects are designed to produce compressed natural gas instead of electricity, which would allow for pipeline injection to take advantage of carbon credit-trading programs such as California’s Low Carbon Fuel Standard program.

In some cases, the production of renewable fuels from anaerobic digesters results in digester coproducts. These coproducts can be marketed and serve to increase revenue and encourage further adoption of digesters. For example, anaerobically digested and composted manure fiber may be used as a peat moss substitute in greenhouse and nursery production, although challenges remain to meet growers’ needs for plant substrates that are standardized, reliable, free of odor and pathogens, and economical. In addition, technologies exist to convert digestate fiber into marketable biopots—biodegradable plant pots that are alternatives to plastic containers used in greenhouses, nurseries, and landscaping markets.

Researchers are developing technologies to extract renewable fuels from manure. These include thermochemical conversion technologies such as combustion, gasification, and pyrolysis (heating without air). While there are advantages of thermochemical conversion, such as destruction of pathogens and pharmaceuticals, the high capital costs of equipment, increased costs to meet air emission limitations, and process inefficiencies are significant barriers to adoption of current thermochemical conversion technologies.

Errata: On August 21, 2023, the table in this article was changed to correct the data for barley acres planted, as well as for acres of barley that were manured and shares of manure-receiving crops. Data in the fourth paragraph also changed to reflect the corrected data on barley.

Increasing the Value of Animal Manure for Farmers, by Teng Lim, Ray Massey, Laura McCann, Timothy Canter, Seabrook Omura, Cammy Willett, Alice Roach, Nigel Key, and Laura Dodson, ERS, March 2023

Agricultural Resources and Environmental Indicators, 2019, by Daniel Hellerstein, Dennis Vilorio, Marc Ribaudo, Marcel Aillery, Daniel Bigelow, Maria Bowman, Christopher Burns, Roger Claassen, Andrew Crane-Droesch, Jacob Fooks, Catherine Greene, LeRoy Hansen, Paul Heisey, Claudia Hitaj, Robert A. Hoppe, Nigel Key, Lori Lynch, Scott Malcolm, William D. McBride, Roberto Mosheim, Richard Nehring, Glenn Schaible, David Schimmelpfennig, David Smith, Stacy Sneeringer, Tara Wade, Steven Wallander, Sun Ling Wang, and Seth J. Wechsler, ERS, May 2019

Farm Practices & Management, USDA, Economic Research Service, October 2023

Policy Instruments for Protecting Environmental Quality, by Steven Wallander, USDA, Economic Research Service, March 2022

Fertilizer Use and Price, by Roberto Mosheim, USDA, Economic Research Service, October 2019

Managing Manure to Improve Air and Water Quality, by Marcel Aillery, Noel Gollehon, Robert Johansson, Jonathan Kaplan, Nigel Key, and Marc Ribaudo, USDA, Economic Research Service, September 2005

Nitrogen Management on U.S. Corn Acres, 2001-10, by Marc Ribaudo, Michael Livingston, and James Williamson, USDA, Economic Research Service, November 2012

Nitrogen in Agricultural Systems: Implications for Conservation Policy, by Marc Ribaudo, Jorge Delgado, LeRoy Hansen, Michael Livingston, Roberto Mosheim, and James Williamson, USDA, Economic Research Service, September 2011

Climate Change Policy and the Adoption of Methane Digesters on Livestock Operations, by Nigel Key and Stacy Sneeringer, USDA, Economic Research Service, February 2011